Getting industrial surge protectors is unlike getting a surge protector for home use or for traveling purposes – there are many considerations to be aware of. While it is important to keep within the allocated budget, it is more critically important to match the right product to operational requirements when it comes to buying industrial surge protection devices.

Procuring the wrong surge protection system for the business environment can be catastrophic whenever there are electrical power issues.

Product-to-Requirements Mismatch – What’s the Impact?

Getting the right enterprise-level surge protectors helps maintain a reliable environment for around-the-clock business operations and continuity.

If the surge protection system fails, critical business operations could be at risk of having extensive and expensive downtimes. Not to mention expensive machinery and equipment, which are also at risk of getting irreparable hardware damage from irregular voltage surges.

At a more serious level, it could even pose dangers to people and communities that are expecting and relying on continuous services. For example, a service disruption at a Telecom level usually brings about many hours of downtime, which can be deadly for people experiencing medical emergencies.

Industrial Surge Protectors VS Home Surge Protectors – What Are the Key Differences?

Surge protectors for homes and offices typically feature common components, including MOVs (Metal-Oxide-Varistors) integrated into the internal wiring to assess the strength of incoming voltages. When the incoming currents hover above safe thresholds, excessive currents are diverted to the ground once the electricity flow has been terminated.

The majority of home-based surge protection devices come with 1500 joules and below and will typically wear out within a couple of years or after one or two strong voltage surges. When sourcing for reliable home surge suppressors, go for those that provide notifications when it is no longer working and will initiate an auto-shutdown so as to prevent surge current from damaging plugged-in devices and appliances.

Some workbench surge protection devices are also built to last for a longer time than home counterparts. Industrial surge protectors function and work along the same principles; one key difference is in the quality of the components and design, which are specifically catered to commercial systems. The environment for commercial systems is hugely different from that of home surge protectors.

These systems usually have a very wide range of power voltages which may go up to 277/480 volts – a far cry from 120/240 volts home-based surge protection devices.

Unlike most affordable home surge suppression devices, which are primarily designed to guard against power spikes, very expensive industrial surge protection systems are typically built to handle lightning strikes. If your industrial applications include data centers, medical facilities, or even transportation systems that require a round-the-clock operation, availability is key to such mission-critical systems.

No matter how good your home surge protection systems are, none of them offer much protection for your expensive home audio system against lightning strikes. Critical industrial applications, on the other hand, mandate that their commercial surge protection systems survive even lightning strikes.

It is widely known that many localities experience loads of power issues which means power grids often provision ‘unclean’ power which could mean triggering voltage spikes or perhaps prolonged brownouts which can be detrimental to sensitive equipment or audio/video systems.

In such cases, getting a power conditioning isolation transformer like Eaton Power Suppress 100 might be your best bet to safeguard industrial applications. Besides offering enhanced equipment protection, such transformers guard against electrical disturbances and electrical noises like RF/EMI.

Surge Protection Devices are typically categorized into 3 types

Categories

Descriptions

Type 1 | Class 1

Designed to discharge partial lightning current by using spark gap technology that produces a waveform of 10/350 μSn

Type 2 | Class II

Designed to guard against widespread overvoltage across certain installations, producing waveform of 8/20 μSn ( usually via MOV technology)

Type 3 | Class III

Usually installed as supplements to Class II devices, such devices have low discharge capacity and offer a combination of voltage waves of 1.20 /50 μSn

Surge protection for industrial applications is never as easy as grabbing a type 3 surge protection device off the shelf. Commercial-grade surge protectors need to be carefully planned and integrated into the overall designs of industrial applications.

Prior to entry into industrial facilities, uncleaned incoming power needs to be checked and cleaned. Additional voltage protection and conditioning must be in place when power enters further into the downstream areas. Employing such a cascading design will minimize unexpected downtimes in the long run. This is especially true in the downstream area where major electrical spikes might occur during day-to-day operations and power cycling of compressors, machinery, or equipment.

A layered approach to surge protection is essential for safeguarding industrial applications. Any unexpected downtime to such applications could be very costly and potentially life-threatening to communities that depend on them.

Risk assessment is one area that is often overlooked when it comes to procuring one that fits industrial applications that are bound by specific laws. Typical risk assessment involved assessing how the probability of getting lightning strikes, and the overall asset value of equipment and utilities that are under protection.

Important Things to Know When Choosing Industrial Surge Protectors

Since industrial surge protectors usually come in a modular form that mounts on DIN rails – there are some key features you will need to know before getting them.

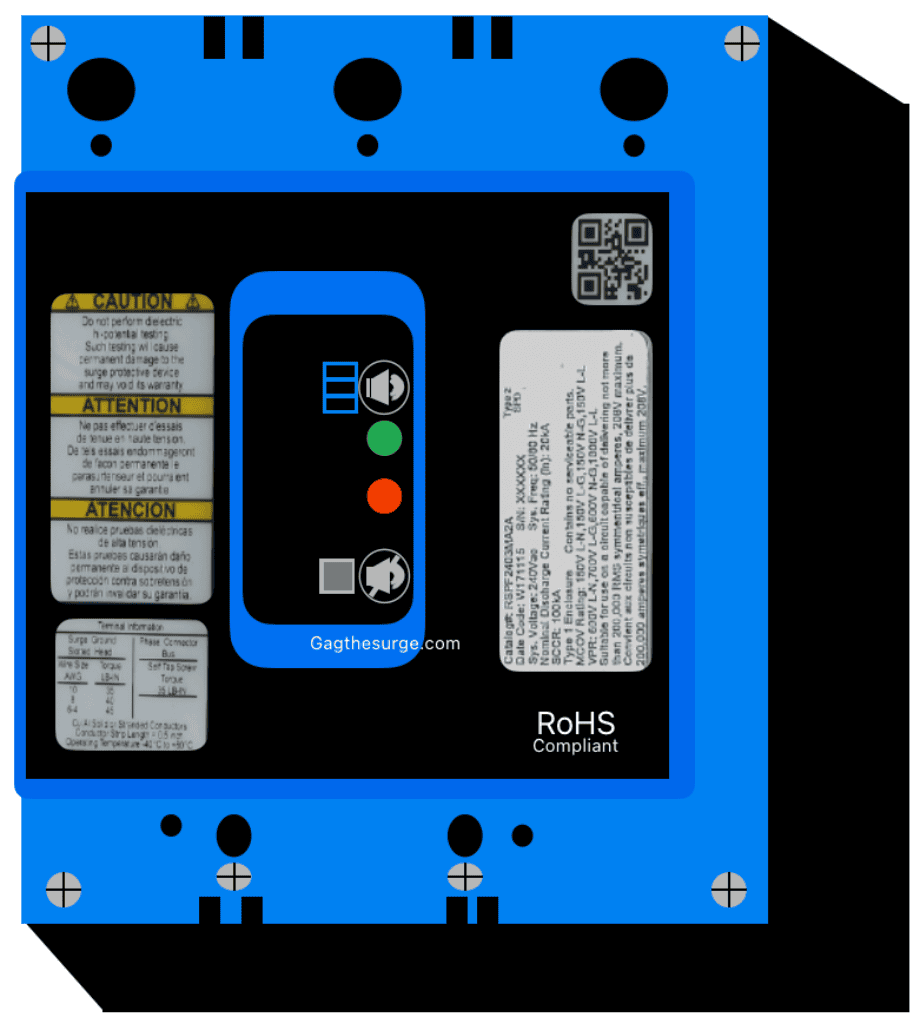

Round-the-clock Alarm and Notifications

Before purchasing surge protectors for commercial use, it is important to choose one that provides visual indications, audio alarms, or even email notifications. Just like typical home surge protection devices, their typical lifespan is usually around 24 months and they must be replaced once they lost their surge protection capabilities.

Removing the surge protectors for bench tests every now and then is impractical and a waste of resources.

Replaceable Modules

Some brands do come with surge protection devices that allow the modular replacement of failed cartridges instead of replacing the whole surge protection device.

Initial Line of Defense

Typical home surge protectors do come with joules of up to 4000 which is hard enough when it comes to withstanding the hit by lightning strikes. This emphasizes the importance of having an initial line of defense against unclean power entering the facilities where industrial applications are hosted. With this in mind, be sure to have a cascading design (that will negate the effects of lightning strikes to the minimum) in your overall surge protection planning for industrial applications.

Clamping Voltage and Response Time

Also known as peak let-through, is the trigger that kickstarts the surge protection. For obvious reasons, always opt for the lowest clamping voltage available. A response time of one nanosecond is the standard – do not go for anything higher than that.

GFCI Circuitry

Such circuitry enables short-circuit detection, which triggers power cut-off – a crucial feature for safeguarding industrial applications.

Programmable and Energy Saving Features

Depending on your industrial applications, these two features may not be essential. If cost-saving and automation form part of the overall design, these two features are definitely worth getting.

Which Brands to Choose

If industrial-grade surge protection is one of your key objectives, then it is not a good idea to start trying out off-brand manufacturers. There are quite a few established brands in the field that you should consider.

If industrial-grade surge protection is one of your key objectives, then it is not a good idea to start trying out off-brand manufacturers. There are quite a few established brands in the field that you should consider.

Eaton is a reputable brand you can count on, and depending on the type you need, its models are generally more affordable if you do not require them to safeguard critical machinery and equipment. Read this review if you are looking for one that protects the entire household against external power surges.

Hager – This is a well-known and reputable brand. Their Type 1/2 combo SPN801 model offers 8 modules, 100 kA Max Discharge, and end-of-life indication.

Sollatek – Their Sollatec SMC1 series is definitely worth checking out. They have quite a good selection of voltage protection devices. Some of their models have settable time delay features that help avoid switching on and off equipment too quickly during voltage fluctuations.

Phoenix Contact – is another well-known brand in the industry that pioneers the Push-in connection features and they have a wide range of Type 1, 2 and 3 surge protection products.

Siemens – Another brand we have reviewed and you should check out. Their FirstSurge FS140 is widely compatible with many brands of load centers and breakers.

No matter which brand you choose, always check the warranty scope for the specific brands and models you have chosen. If you do not need industrial level surge protection but something stronger than the typical ones, you might want to consider this 4800 Joules surge protector which is quite decent in terms of quality and is affordable.