Published By: Editorial Team | Last updated on June 5, 2025 and reviewed by Editorial Team

Have you ever wondered what the basic functions and features of a power conditioner are? Imagine your home’s electric system as a busy highway. Without an advanced level voltage regulator, traffic jams and accidents can occur. Power conditioners act like traffic controllers, ensuring smooth flow and safety. They maintain electric stability, enhancing home safety and equipment efficiency.

Power conditioners remove disturbances from the power line, offering a refreshing boost to your devices. With the rise in demand for microprocessor-based gadgets, power conditioning has become crucial in protecting our prized electronics from voltage fluctuations.

Guide to Power Conditioners

Have you ever wondered why your electronic devices misbehave? I’ve seen it many times. The issue usually comes from the power supply. Let’s explore how power conditioners can help improve such a situation.

What is a Power Conditioner?

Definition and Functionality

A power conditioner acts like a vigilant guardian for your electronics. It regulates voltage, reduces noise, and filters out disturbances. Imagine it as a filter that ensures only clean power reaches your devices. This protection prevents damage from power fluctuations and electrical noise.

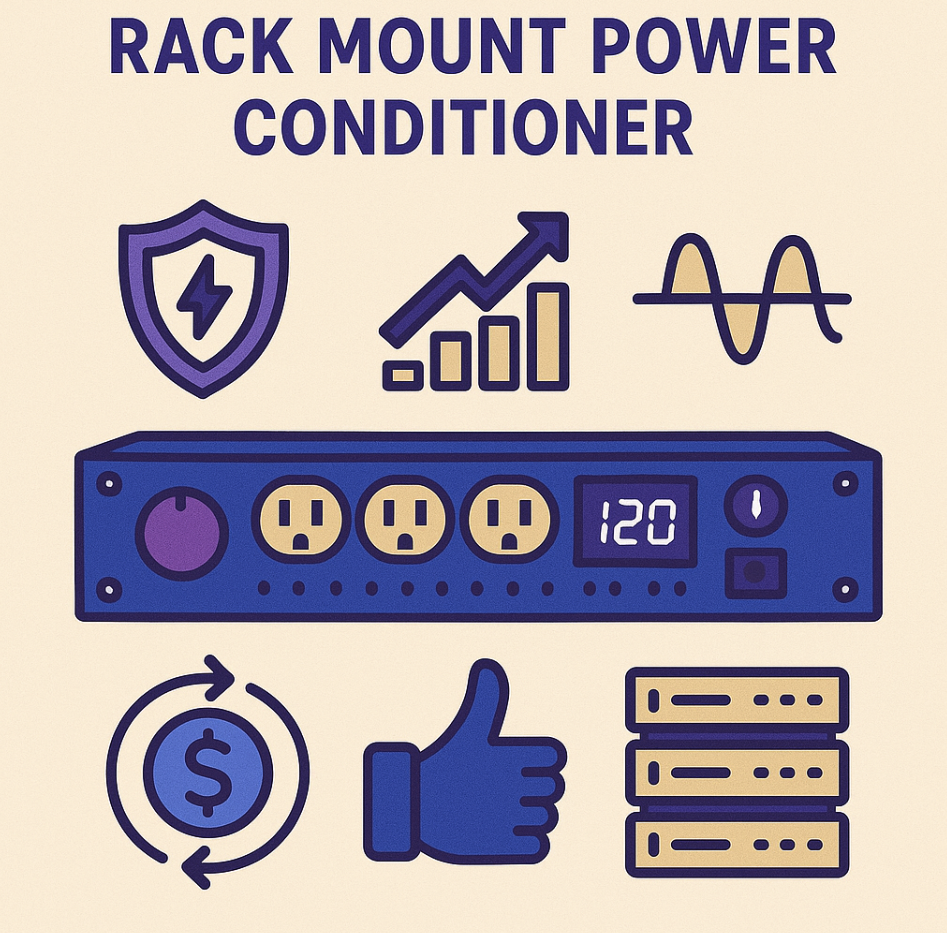

Types of Power Conditioners

Power conditioners come in various forms:

-

Electronic: These are compact and ideal for home use.

-

Transformer-based: Perfect for industrial applications, offering robust protection.

-

Line conditioners: They focus on removing electrical anomalies, ensuring smooth operation.

How Power Conditioners Differ from Surge Protectors

Key Differences

Many people confuse power conditioners with surge protectors. While both offer protection, they serve different purposes:

-

Power Conditioners: Focus on cleaning and stabilizing the power supply.

-

Surge Protectors: Primarily guard against sudden voltage spikes.

Common Misconceptions

I often hear people say, “I have a surge protector, so I’m covered.” This isn’t entirely true. Surge protectors don’t address voltage fluctuations or electrical noise. Power conditioners do, making them essential for sensitive equipment.

Use Case 1: Home Theater Systems

Ever sat down to enjoy a movie night, only to be interrupted by an annoying hum or flickering screen? I’ve been there, and it’s frustrating. The culprit often lies in the power supply. Power conditioners can transform your home theater experience by ensuring a clean and stable power flow.

Relevant Info

Enhancing Audio and Visual Quality

Power conditioners remove noise and interference, providing a cleaner power supply. This improvement enhances both audio and visual quality. Imagine watching your favorite film with crystal-clear sound and vibrant visuals. The difference is remarkable.

|

Feature |

Without Conditioner |

With Conditioner |

|---|---|---|

|

Audio Clarity |

Distorted |

Clear |

|

Visual Quality |

Flickering |

Stable |

|

Electrical Noise Level |

High |

Low |

Why is it Useful?

Protecting Expensive Equipment

Home theater systems are a significant investment. Protecting them from power fluctuations is important. Power conditioners serve as a safeguard, protecting against damage caused by voltage spikes and electrical noise. They ensure that your equipment lasts longer and performs better.

In my experience, investing in a power conditioner saves money in the long run by reducing the need for repairs.

Common Concerns

Cost vs. Benefit

Some might wonder if the cost of a power conditioner is justified. I understand this concern. However, consider the potential cost of replacing damaged equipment. The benefits of improved performance and protection outweigh the initial investment.

Power conditioners not only enhance your viewing experience but also provide peace of mind.

What Else to Know

Installation Tips

Ever tried setting up a power conditioner and felt overwhelmed? I’ve been there. Let me guide you through some straightforward tips to make the process smooth and efficient.

-

Choose the Right Location: Place your power conditioner close to the equipment it will protect. This minimizes the length of power cables, reducing potential interference.

-

Check Compatibility: Ensure the power conditioner matches the voltage and current requirements of your devices. This step prevents any mismatch that could lead to inefficiencies.

-

Secure Connections: Use high-quality cables and connectors. Loose connections can introduce noise and reduce the effectiveness of the power conditioner.

-

Follow Manufacturer Guidelines: Always refer to the installation manual. Manufacturers provide specific instructions tailored to their products, ensuring optimal performance.

-

Regular Maintenance: Schedule periodic checks. Dust and debris can accumulate, affecting performance. Keeping the unit clean ensures longevity and reliability.

By following these tips, you’ll maximize the benefits of your power conditioner, ensuring your home theater system delivers the best possible experience.

Remember, a little effort in installation goes a long way in protecting your valuable equipment.

Use Case 2: Recording Studios

Ever wondered why your studio recordings sometimes have an annoying hum or noise? I’ve faced this issue countless times. The culprit often lies in the power supply. A power conditioner can transform your recording studio experience by ensuring a clean power supply.

Relevant Info

Ensuring Clean Power Supply

In a recording studio, clean power is crucial. It ensures that your equipment functions optimally without interference. Imagine working on a track and suddenly hearing a hum or noise. It disrupts the creative flow and affects the final output.

Power conditioners eliminate these disturbances, providing a stable and clean power supply. This stability enhances the quality of your recordings, making them sound professional and polished.

|

Equipment |

Without Conditioner |

With Conditioner |

|---|---|---|

|

Microphones |

Hum present |

Hum-free |

|

Monitors |

Noise interference |

Clear sound |

|

Processors |

Unstable power |

Stable power |

Why is it Useful?

Reducing Noise and Interference

Noise and interference can ruin a perfect take. I’ve experienced this firsthand. A power conditioner acts as a shield, reducing noise and interference. It ensures that your recordings are crisp and clear. This noise reduction enhances the overall sound quality, making your studio work stand out.

Investing in a power conditioner is like investing in the longevity of your studio gear. It prevents sudden power jolts, prolonging the life of your microphones, monitors, and processors.

Common Concerns

Compatibility with equipment

Compatibility is a common concern when integrating a power conditioner into your studio setup. I’ve seen many people worry about whether their equipment will work seamlessly with a conditioner.

The key is to ensure that the power conditioner matches the voltage and current requirements of your studio gear. This compatibility prevents any mismatch that could lead to inefficiencies or damage. Always check the specifications and consult with experts if needed.

Address these concerns to maximize the benefits of a power conditioner in your studio. A little setup effort enhances your creative journey.

What Else to Know

Maintenance Requirements

Ever wondered why some studios experience power issues despite having a power conditioner? I’ve seen it happen. The secret often lies in maintenance. Proper upkeep ensures your power conditioner performs at its best.

-

Regular Cleaning: Dust can accumulate and affect performance. I recommend cleaning your power conditioner every few months. Use a soft cloth to wipe away dust and debris. This simple step keeps your unit running smoothly.

-

Check Connections: Loose connections can introduce noise. Inspect cables and plugs regularly. Ensure everything is secure. This prevents unwanted interference and maintains a clean power supply.

-

Monitor Performance: Keep an eye on how your equipment behaves. If you notice changes in sound or power stability, it might be time for a check-up. Early detection of issues can save you from costly repairs.

-

Professional Servicing: Consider professional maintenance annually. Experts can spot potential problems you might miss. This proactive approach extends the life of your power conditioner.

By following these maintenance tips, you ensure your power conditioner continues to protect your valuable studio gear. Remember, a little effort in upkeep goes a long way in preserving your creative investments.

Use Case 3: Medical Equipment

Have you ever wondered why hospitals invest heavily in power solutions? Imagine a life-saving machine suddenly malfunctioning due to a power surge. The consequences could be dire.

Power conditioners play a vital role in ensuring that medical devices operate without interruption.

Relevant Info

Importance of Stable Power

In the medical field, stable power is not just a convenience; it’s a necessity. Medical equipment, from MRI machines to ventilators, relies on consistent power to function correctly.

A power conditioner ensures that these devices receive a clean and stable power supply. This stability prevents disruptions that could lead to inaccurate readings or equipment failure.

|

Equipment |

Without Conditioner |

With Conditioner |

|---|---|---|

|

MRI Machines |

Unstable readings |

Accurate results |

|

Ventilators |

Risk of failure |

Reliable support |

|

Monitors |

Flickering screens |

Clear displays |

Why is it Useful?

Preventing Malfunctions

Preventing malfunctions in medical equipment is critical. I’ve witnessed how power conditioners act as a safeguard, reducing the risk of equipment failure. They filter out electrical noise and stabilize voltage, ensuring that machines operate smoothly.

Hospitals need dependable power because every moment matters in healthcare. Investing in a power conditioner helps them dodge pricey repairs and ensures patient safety.

Common Concerns

Reliability Issues

Some might question the reliability of power conditioners. I understand these concerns. However, the benefits far outweigh the risks. Power conditioners are designed to handle fluctuations and disturbances, providing a consistent power supply.

The reduction of ground loops and other electrical problems decreases the probability of compromised equipment performance. This assurance allows hospitals to rely on their medical devices to function as designed.

What Else to Know

Compliance Standards

Have you ever wondered why compliance standards matter for power conditioners in medical settings? I’ve seen firsthand how crucial these standards are. They ensure that power conditioners meet specific safety and performance criteria, which is vital for medical equipment.

-

Regulatory Requirements: Power conditioners must adhere to strict regulations. These include standards set by organizations like the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL). Compliance ensures that power conditioners provide reliable protection against electrical disturbances.

-

Safety Assurance: Compliance standards guarantee that power conditioners are safe to use with sensitive medical devices. They prevent issues like overheating and electrical faults, which could compromise patient safety. By meeting these standards, hospitals can trust that their equipment will function without interruption.

-

Performance Consistency: Standards ensure that power conditioners deliver consistent performance. They eliminate voltage fluctuations and electromagnetic interference, which can affect the accuracy of medical equipment. According to a study, power conditioners remove harmonic distortions, resulting in precise readings and reliable operation.

-

Quality Certification: Certified power conditioners undergo rigorous testing. This certification process verifies their ability to handle electrical noise and voltage irregularities. Hospitals can rely on certified units to maintain stable power, reducing the risk of equipment failure.

Get a grip on compliance standards so you can choose the best power conditioners for medical use, ensuring your equipment is protected and everyone stays safe.

Use Case 4: Data Centers

Ever wondered why data centers invest heavily in power solutions? I’ve seen firsthand how crucial stable power is for maintaining data integrity. Imagine a server room suddenly losing power or experiencing fluctuations.

The consequences could be catastrophic, leading to data loss or corruption. Power conditioners play a vital role in ensuring that data centers operate without interruption.

Relevant Info

Managing Power Loads

In data centers, managing power loads is not just a convenience; it’s a necessity. Servers and networking equipment rely on consistent power to function correctly. A power conditioner ensures that these devices receive a clean and stable power supply. This stability prevents disruptions that could lead to data corruption or loss.

According to a study, power conditioners eliminate voltage irregularities and electromagnetic interference, which are common culprits of data integrity issues.

|

Equipment |

Without Conditioner |

With Conditioner |

|---|---|---|

|

Servers |

Unstable performance |

Reliable operation |

|

Networking Gear |

Frequent resets |

Consistent uptime |

|

Storage Devices |

Data corruption |

Secure data |

Why is it Useful?

Ensuring Data Integrity

Ensuring data integrity in data centers is critical. I’ve witnessed how power conditioners act as a safeguard, reducing the risk of data corruption. They filter out electrical noise and stabilize voltage, ensuring that servers and storage devices operate smoothly.

In a data center, every second matters, so having dependable power is key. Investing in a power conditioner helps avoid pricey data recovery and keeps everything secure.

Common Concerns

Scalability

Some might question the scalability of power conditioners. I understand these concerns. However, the benefits far outweigh the risks. Power conditioners are designed to handle fluctuations and disturbances, providing a consistent power supply.

They help prevent ground loops and other electrical issues that could affect gear performance. By addressing these scalability concerns, data centers can rely on their systems functioning as intended.

Use Case 5: Industrial Applications

Ever walked through a bustling factory and wondered how all that heavy machinery keeps running smoothly? I’ve seen firsthand how crucial stable power is in industrial settings. Imagine a sudden power drop halting production lines.

The impact could be costly. Power conditioners play a vital role in maintaining efficiency and minimizing downtime.

Relevant Info

Handling Heavy Machinery

In industries, handling heavy machinery requires consistent power. These machines rely on a stable electrical supply to function optimally. Power conditioners ensure that equipment receives clean power, free from external electrical noise.

This stability prevents disruptions that could lead to costly repairs or production delays.

|

Machinery Type |

Without Conditioner |

With Conditioner |

|---|---|---|

|

Conveyor Belts |

Frequent Stalls |

Smooth Operation |

|

CNC Machines |

Inaccurate Cuts |

Precision Work |

|

Assembly Lines |

Downtime |

Continuous Flow |

Why is it Useful?

Minimizing Downtime

Downtime in industrial applications can result in substantial financial losses. I’ve witnessed how power conditioners act as a safeguard, reducing the risk of unexpected shutdowns.

They filter out electrical noise and stabilize voltage, ensuring that machinery operates smoothly. This reliability is essential in maintaining productivity and meeting deadlines.

Common Concerns

Energy Efficiency

Some might question the energy efficiency of power conditioners. I understand these concerns. However, the benefits far outweigh the risks.

Power conditioners are designed to handle fluctuations and disturbances, providing a consistent power supply. They reduce the likelihood of ground loops and other electrical issues that can compromise equipment performance.

What Else to Know

Custom Solutions

Ever walked through a factory and noticed the unique machinery humming away? I’ve seen how each piece of equipment demands specific power needs.

Power conditioners offer custom solutions tailored to these unique requirements, ensuring optimal performance.

-

Tailored Design: Every industrial setup has distinct power demands. Power conditioners can be customized to match these needs, providing precise voltage regulation and noise filtering. This customization ensures that your machinery operates smoothly, reducing the risk of unexpected shutdowns.

-

Adaptability to Environment: Industrial environments vary greatly. Whether dealing with extreme temperatures or high humidity, power conditioners can be designed to withstand these conditions. This adaptability ensures consistent performance, even in challenging settings.

-

Integration with Existing Systems: Seamless integration is important. Power conditioners can be configured to work with your current infrastructure, minimizing disruption during installation. This compatibility enhances efficiency and reduces downtime.

-

Scalability for Growth: Planning for future expansion? Custom power conditioners can scale with your business. They handle increased power loads, ensuring that as your operations grow, your power supply remains stable and reliable.

Consider the impact of weather-related outages. Studies show that blackouts, especially those caused by severe weather, often last eight hours or more. This downtime can cripple production. Custom power solutions, including backup systems, ensure that your operations continue uninterrupted.

|

Feature |

Standard Solution |

Custom Solution |

|---|---|---|

|

Voltage Regulation |

General |

Precise |

|

Environmental Fit |

Limited |

Tailored |

|

System Integration |

Basic |

Seamless |

|

Scalability |

Fixed |

Flexible |

Investing in custom power conditioners is like providing your industrial setup with a safety net against unexpected power issues. This forward-thinking step not only boosts productivity but also protects your expensive equipment from damage.

Use Case 6: Office Environments

Ever walked into an office and wondered why everything runs so smoothly? I’ve seen firsthand how crucial a stable power supply is for supporting IT infrastructure. Imagine computers crashing or networks failing due to power fluctuations.

The impact on productivity could be disastrous. A power conditioner can save the day by ensuring that your office environment operates without interruption.

Relevant Info

Supporting IT Infrastructure

In modern offices, IT infrastructure forms the backbone of daily operations. Computers, servers, and networking equipment rely on consistent power to function correctly. A power conditioner ensures these devices receive a clean and stable power supply. This stability prevents disruptions that could lead to data loss or system failures.

According to studies, power conditioners eliminate voltage irregularities and electromagnetic interference, which are common culprits of IT issues.

|

Equipment |

Without Conditioner |

With Conditioner |

|---|---|---|

|

Computers |

Frequent crashes |

Reliable operation |

|

Servers |

Data corruption |

Secure data |

|

Networking Gear |

Connectivity issues |

Consistent uptime |

Why is it Useful?

Enhancing Productivity

Enhancing productivity in office environments is essential. I’ve witnessed how power conditioners act as a safeguard, reducing the risk of unexpected downtime. They filter out electrical noise and stabilize voltage, ensuring that office equipment operates smoothly. This reliability boosts productivity and helps meet deadlines.

Common Concerns

Space Constraints

Some might worry about space constraints when integrating a power conditioner with surge protection. I understand these concerns. However, modern power conditioners come in compact designs that fit seamlessly into office setups.

They reduce the likelihood of ground loops and other electrical issues that can compromise equipment performance.

By addressing these concerns, you can maximize the benefits of a power conditioner in your office environment. Remember, investing in a power conditioner is like investing in the efficiency and longevity of your office operations.

What Else to Know

Integration with Existing Systems

Ever tried integrating new technology into your office and felt overwhelmed? I’ve been there. Power conditioners can seamlessly fit into your existing systems, enhancing efficiency without causing disruptions.

-

Assess Compatibility: Start by evaluating your current setup. Ensure the power conditioner matches the voltage and current needs of your devices. This step prevents mismatches that could lead to inefficiencies.

-

Plan the Layout: Position the power conditioner close to the equipment it will support. This reduces cable length and minimizes potential interference. A well-planned layout ensures smooth integration.

-

Use Quality Connections: Invest in high-quality cables and connectors. Secure connections prevent noise and maintain the power conditioner’s effectiveness. This attention to detail enhances overall performance.

-

Follow Compliance Standards: Adhere to standards like IEC 60601-1 for safety and reliability. These guidelines ensure that your power conditioner operates safely with sensitive equipment.

-

Monitor and Adjust: Regularly check the system’s performance. Make adjustments as needed to optimize efficiency. This proactive approach keeps your office running smoothly.

Go through these steps to seamlessly incorporate a power conditioner into your workspace. This will not only improve productivity but also protect your essential devices.

Summing Up

Power conditioners stabilize power, reduce noise, and protect against surges, making them indispensable in various settings. I encourage you to explore these specific use cases and see the benefits firsthand.

Investing in a power conditioner not only safeguards your equipment but also enhances performance and longevity. Leverage the power of conditioning and transform your electronic experience today.